Eco-Friendly Dry Ice Cleaning That Saves You Time and Money

Step-by-Step Process

-

1 - Kinetic Energy:

High-velocity dry ice particles impact the contaminated surface.

-

2 - Thermal Shock:

The extreme cold temperature of the dry ice (-79°C) causes contaminants to contract and become brittle.

-

3 - Sublimation:

Upon impact, the dry ice sublimates (turns from solid to gas), expanding nearly 800 times in volume.

-

4 - Micro-Explosions:

This rapid expansion helps lift contaminants off the surface without abrasion.

Why this process is effective?

Non-Abrasive Cleaning

Surfaces are cleaned without damage, preserving the integrity of equipment.

Deep Cleaning Capability

The combination of thermal shock and kinetic energy removes even stubborn contaminants.

Environmentally Friendly

Eliminates the need for chemical solvents and reduces hazardous waste.

Manual Use Setup

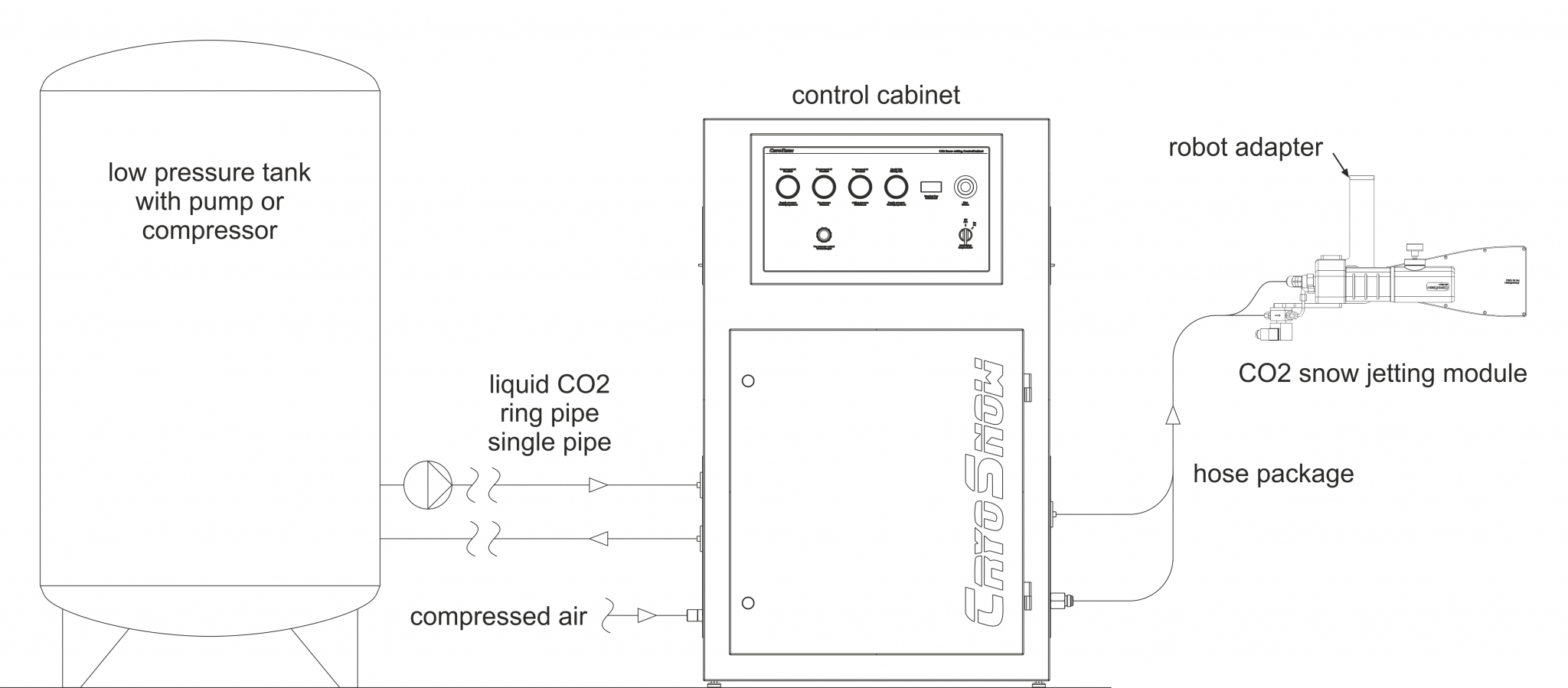

Automation Use Setup

Adjustable Parameters for Optimal Cleaning

-

Blasting Pressure:

Ranges from 2 to 16 bar, allowing for gentle cleaning or more aggressive removal.

-

Dry Ice Feed Rate:

Control the amount of dry ice used, optimising consumption and efficiency.

-

Nozzle Selection:

Various nozzle designs are available to target different types of contaminants and surfaces.